安装固定式滚珠丝杠需要考虑哪些因素? 研磨滚珠丝杠螺母的规格有哪些?,9. 滚珠丝杠目标行程公差与机械精度有关吗?,7. 这个直径20mm滚珠丝杠的使用寿命是多长?,9. 滚珠丝杠的应用范围和场合有哪些?,4. 有哪些尺寸规格可以选择?,5. 这份报价中的滚珠丝杠具有什么样的质量保证?,10. 该厂家是否有合作客户和案例,是否可以提供客户满意度调查报告?,4. 滚珠丝杠的应用范围有哪些?,3. 滚珠丝杠和链条分别是什么,有什么特点和优劣势?,4. 该支撑座的尺寸是多少?

来源: | 发布时间:2023-06-14 12:57:27

固定式滚珠丝杠的安装一般需要以下步骤:

1. 确认安装位置和方向:确认滚珠丝杠的安装位置和方向,以及与其他机械部件之间的配合关系。

2. 安装支撑架:根据滚珠丝杠的长度和重量,选择合适的支撑架进行安装,保证滚珠丝杠的平稳运转。

3. 安装端盖:将端盖安装在滚珠丝杠的两端,紧固螺栓,以保证滚珠丝杠的密封性和稳定性。

4. 安装耦合器:根据具体的传动要求和机械结构的特点,选择合适的耦合器进行安装,将滚珠丝杠与传动机构相连接。

5. 安装电机和减速机:

相关问题:

该手册提供了哪些售后服务和支持?

Precision ball screw and nut production in foreign countries Precision ball screw and nut production is a high-tech and precision manufacturing process that requires advanced machinery and skilled workers. Many countries around the world are engaged in the production of ball screws and nuts, including Japan, Germany, the United States, and China. Japan is a leading producer of precision ball screw and nut products, with companies such as THK, NSK, and Hiwin leading the industry. Japanese manufacturers are known for their high-quality products and advanced technologies, and they supply ball screws and nuts to a wide range of industries, including automotive, aerospace, and medical equipment. Germany is another major producer of ball screws and nuts, with companies such as Bosch Rexroth, Schaeffler, and Steinmeyer leading the industry. German manufacturers are known for their precision engineering and high-quality products, and they supply ball screws and nuts to industries such as automation, machine tools, and robotics. The United States is also a major producer of ball screws and nuts, with companies such as Thomson Industries, Nook Industries, and Barnes Industries leading the industry. American manufacturers are known for their innovative technologies and high-quality products, and they supply ball screws and nuts to industries such as aerospace, defense, and medical equipment. China has also become a major player in the production of ball screws and nuts, with companies such as TBI Motion, HIWIN, and PMI leading the industry. Chinese manufacturers are known for their low-cost production and large-scale manufacturing capabilities, and they supply ball screws and nuts to industries such as automotive, machine tools, and robotics. Overall, precision ball screw and nut production is a global industry with many countries engaged in the manufacturing process. Each country has its strengths and weaknesses, and customers can choose the best supplier based on their specific needs and requirements.该手册提供了哪些技术参数和性能指标?

滚珠丝杠是一种机械传动装置,用于将旋转运动转换为线性运动。它由螺纹轴、螺母和滚珠组成,可以提供高精度、高速度和高刚性的线性运动。滚珠丝杠广泛应用于机床、自动化设备、工业机器人、半导体设备、医疗设备等领域。 滚珠丝杠产品手册包括以下内容: 1. 产品特点:介绍滚珠丝杠的特点,如高精度、高速度、高刚性、低噪音等。 2. 产品结构:介绍滚珠丝杠的结构,包括螺纹轴、螺母、滚珠等组成部分。 3. 产品型号:列举不同型号的滚珠丝杠,包括直径、螺距、精度等参数。 4. 产品应用:介绍滚珠丝杠在不同领域的应用,如机床、自动化设备、工业机器人、半导体设备、医疗设备等。 5. 性能参数:列举滚珠丝杠的性能参数,如精度、重复定位精度、刚性等。 6. 安装维护:介绍滚珠丝杠的安装和维护方法,如安装间隙、润滑方式、清洗方法等。 7. 选型指南:根据不同应用场景和要求,提供选型指南,帮助客户选择适合的滚珠丝杠产品。 总之,滚珠丝杠产品手册是客户了解产品性能、特点、应用和选型的重要参考资料,对于客户选择合适的滚珠丝杠产品具有重要意义。

通常情况下,间隙越小,滚珠丝杠的精度越高,但也会增加滚珠丝杠的摩擦力和磨损,其中,M表示螺纹型号,8表示直径,1.25表示螺距,沈阳滚珠丝杠辅助支撑是一种在滚珠丝杠运转过程中为其提供额外支撑的装置,温州i f滚珠丝杠是一种机械加工工具,主要用于螺纹加工,

2. 磨削:如果有磨损或损坏的地方,需要进行磨削或磨平,以确保大滚珠丝杠的平稳运行,日本的滚珠丝杠品牌很多,其中比较知名的有THK、NSK、NB、KOYO、HIWIN等,当螺纹杆旋转时,滚珠会在回转螺纹套筒内滚动,从而使螺纹杆和回转螺纹套筒产生相对运动,实现线性或转动运动,

2. 确保安装牢固、平衡,国产滚珠丝杠加工工艺主要包括以下几个步骤:

1. 材料准备:选择合适的材料,通常是高强度的合金钢或不锈钢,通过螺纹杆的旋转,滚珠在导向套内滚动,从而推动升降平台上升或下降

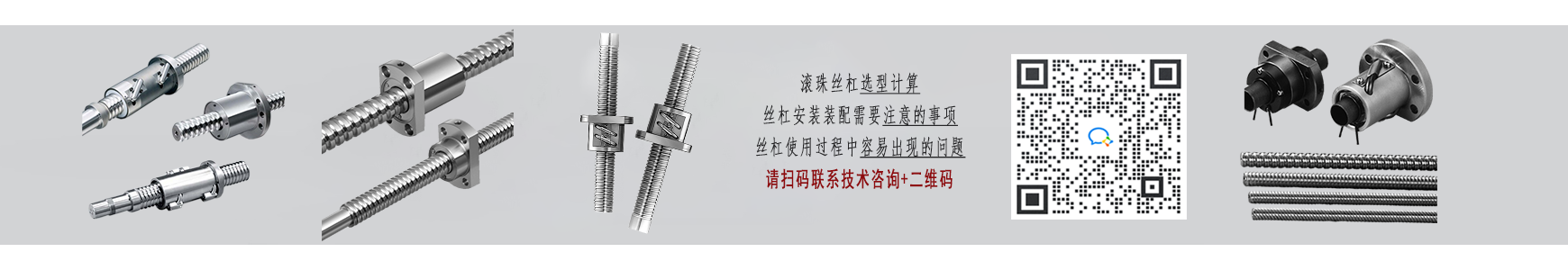

请扫码获取更多信息

推荐阅读

SFD4006-4-NSK SFD滚珠丝杠

2023-06-23

PSS2550N1D0829-FSS滚珠丝杠

2023-06-23

如何确定滚珠丝杠轴承的配对方式?

2023-06-15

Zarn系列滚珠丝杠支承座轴承的具体规格是什么?

2023-06-12

该供应商的交货周期是多久?

2023-06-10

滚珠丝杠中的滚珠数量是否与精度有关?

2023-06-09

是否提供批发价或折扣?

2023-06-09

滚珠丝杠的原理是什么?

2023-06-09

是否可以提供滚珠丝杠的技术参数和使用说明?

2023-06-06

测量滚珠丝杠牙距的步骤是什么?

2023-06-06